AI Applications in Manufacturing: Use Cases & Examples

What if you could process huge amounts of data within seconds? Imagine the limitless possibilities it can bring to your manufacturing business when every decision is data-informed, and every system operates at peak efficiency. AI applications can make this possible! With its ability to streamline every process, from predictive maintenance to supply chain optimization, AI is opening new doors into the future.

In this blog, we’ll explore some of the most impactful AI applications in the manufacturing industry and examples of AI driving innovation! In this three-minute read, explore new opportunities for your manufacturing company with AI!

Don’t Stay Behind! Unlock Business Growth, Efficiency & Innovation With AI.

How are AI Applications Revolutionizing the Manufacturing Industry?

1,812 petabytes (PB) of data every year – that’s how much the manufacturing industry alone generates! AI analytics can process this humongous amount of data within a few seconds. AI in manufacturing industry leverages cutting-edge technologies to optimize operational efficiency. Its biggest superpower is its ability to analyze market patterns. It then provides strategic recommendations for optimization. This has a radical impact in enhancing productivity and decision-making.

One of AI’s most transformative applications is Predictive Maintenance. Here, AI tools analyze equipment data to forecast potential malfunctions. This proactive approach significantly improves efficiency. It also enables manufacturers to enhance production schedules and reduce downtime.

In supply chain management, AI-driven cobots are revolutionizing assembly lines. They automate tasks with precision and speed. These robots can assimilate to changing market needs, guaranteeing businesses stay ahead of the curve.

AI-powered QC systems are also creating waves and raising the bar for quality. They can locate flaws and police the quality of the final product. In smart manufacturing, these systems track workflow in real time. Thus, allowing manufacturers to make necessary adjustments to cut waste and prevent damage.

The manufacturing industry is always eager to welcome new technology. Its most recent venture has been in the realm of generative AI. Major players like Eaton, Bosch, ABB, and Siemens have already started implementing generative AI. They use it at various departments in their production facilities to boost productivity.

As for the future, AI in the manufacturing market is estimated to reach USD 20.8 billion by 2028. Research by MarketsandMarkets suggests that the industry will grow at a CAGR of 45.6% between 2023 and 2028.

Start Your AI Journey Cost-Effectively and With Minimized Risks.

What are the Applications of AI in Manufacturing?

AI is remolding the manufacturing industry by providing unparalleled efficiency boosts and top-notch product quality. So much so that it has led to smarter factories, often referred to as “Industry 4.0.” Here are the most impactful AI applications in manufacturing:

1. Predictive Maintenance

Data from sensors embedded in machinery predict potential equipment failure. This is the power of AI-powered predictive maintenance systems. ML models analyze datasets such as vibrations, temperature, and pressure. They use these datasets to sniff out patterns that point to malfunctions. Thus, preparing manufacturers for machinery failure, reducing downtime, and cutting maintenance costs.

For example, General Motors uses ML to predict malfunctions in production line robots. Thus, reducing unexpected shutdowns.

2. Quality Control and Defect Detection

As mentioned earlier, QC systems run a set of procedures to ensure that a product is of good quality. AI-driven QC systems use computer vision to inspect products in real time. It can detect flaws missed by the human eye. It addresses surface imperfections, misalignments, irregularities, and more. Thus, optimizing all-round product quality and reducing waste.

BMW exemplifies this application with its AI-driven cameras on assembly lines. These cameras check for defects in vehicle parts, enhancing inspection accuracy.

3. Robotics and Automation

This is the earliest application of AI in manufacturing industry. Cobots powered by AI perform repetitive or risky tasks in place of humans. They can also work alongside human employees to improve efficiency and safety. These robots memorize datasets and perfect their performance over time. This makes them the perfect handyman for welding, painting, or material handling.

Cobots are being extensively used to improve the electronics assembly process for example. These bots are instilled into the robotic arms that assemble the electronic components.

4. Generative Design

This is a relatively new domain of AI. Its implementation in the manufacturing industry is not widespread. Yet its popularity has spread like wildfire. Generative design uses AI-driven algorithms to explore a wide array of design solutions. This tool has become the engineer’s best friend. They just have to feed project constraints, such as materials, cost, and durability requirements into the system. The AI system will then generate advanced designs that meet the engineers’ criteria. Thus, paving the way towards lighter, stronger, and cost-effective products.

General Motors uses Autodesk’s generative design software. With this, they create lightweight, durable vehicle components at reduced costs.

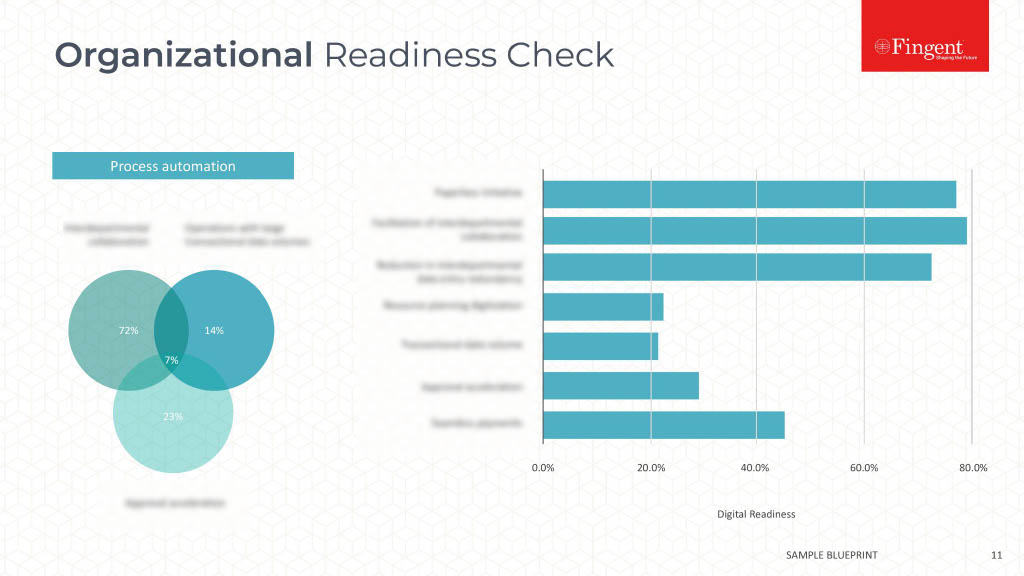

5. Process Automation and Optimization

AI-powered systems can analyze manufacturing processes in real time. In turn, they send appropriate feedback to manufacturers. They also adjust features like speed, temperature, and pressure to improve production efficiency. This level of automation enables manufacturers to work towards models with lesser energy consumption. These sustainable models can also increase output quality and cut waste production.

Tesla’s Gigafactories are a case in point. These factories use AI systems to enhance battery production processes. Thus, optimizing product consistency and cutting material waste production.

6. Energy Efficiency Management

Sustainability is an evergreen trend across all industries. The more sustainable a business is, the more market value it acquires. AI can track energy consumption across manufacturing facilities. It also suggests actions to optimize consumption. AI locates energy inefficiency centers in real-time, controlling heating, lighting, and other systems. Thus, reducing power consumption and contributing to sustainability goals.

Siemens uses AI-powered energy management systems to practice sustainability. The DynaGrid system in Siemens factories cuts operational costs and minimizes environmental impact.

Smart Factory: How Is It Impacting The Manufacturing Industry?

Use Cases of AI in the Manufacturing Industry

The integration of AI in manufacturing is shifting the industry’s paradigm and opening up listless possibilities. Here are the top 3 AI use cases in manufacturing:

1. Digital Twins Improve Efficiency

AI is enabling manufacturers to proactively track and predict equipment failures. It does this by using advanced predictive analytics and machine learning algorithms. A key concept in predictive maintenance is the digital twin.

A digital twin is a virtual replica of a physical asset like an equipment. The twin captures real-time data from the equipment. It then assists AI in analyzing patterns, identifying anomalies, and predicting potential malfunctions.

By leveraging digital twin technology and advanced analytics, companies can wield the sword of ultimate efficiency. They can predict equipment failures, optimize maintenance schedules, and boost operational proficiency.

2. AI-driven Defect Detection

Computer vision uses high-resolution cameras to track the production process in detail. AI-driven defect detection taps into computer vision to identify product flaws that the human eye might miss. The detector will trigger correcting measures automatically, thus reducing product recalls. Detecting anomalies at their earliest stage helps prevent workplace hazards and improves worker safety at factories.

AR overlays are another AI-based system that is proving vital. It compares actual assembly parts with optimal parts to reveal any quality variance. AR can also assist with remote training and support for technicians to connect with those at a facility and guide them.

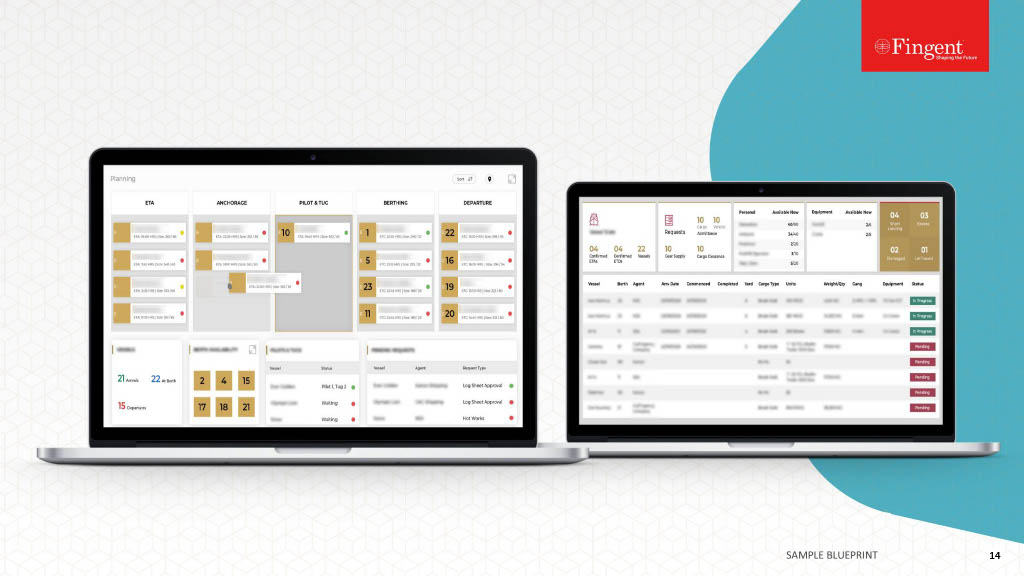

3. Creating an Efficient Supply Chain

AI in supply chain management optimizes demand predictions, inventory management, and logistics. Artificial intelligence can forecast optimal delivery routes, monitor driver performance in real time, and assess traffic reports to predict accurate delivery times. AI can also give manufacturers great control over their supply chain. This ranges from inventory planning to product tracking and management. They can set up a real-time supplier assessment and monitoring model. The model will report supplier failure and assess the repercussions of supply chain disruption.

Common FAQs: Application of AI in Manufacturing

1. How does AI Optimize Quality Control in Manufacturing?

Computer vision and machine learning algorithms can inspect products in real time. They can identify defects like surface imperfections, dimensional errors, or misalignments. Their detections are more accurate and consistent than human inspections. This improves the quality of the product. This in turn translates to happy customers.

2. How does Predictive Maintenance Use AI?

AI enables predictive maintenance to monitor equipment and predict potential malfunctions. AI systems can analyze datasets from sensors to predict when maintenance is necessary. This dataset includes the rate of vibration, temperature, and pressure of the machinery. Predictive maintenance makes an impact in three main ways:

- Reduced downtime

- Lowered repercussion costs

- Extended durability of equipment

3. What Role does AI Play in Supply Chain Management?

AI optimizes factory supply chains to forecast demands, manage inventory, and enhance logistics. ML algorithms analyze legacy data, market trends, and external factors. This enables it to accurately predict demand. It also ensures the maintenance of inventory levels to prevent overstocking or shortages. AI has the foresight to identify and mitigate potential supply chain turmoil.

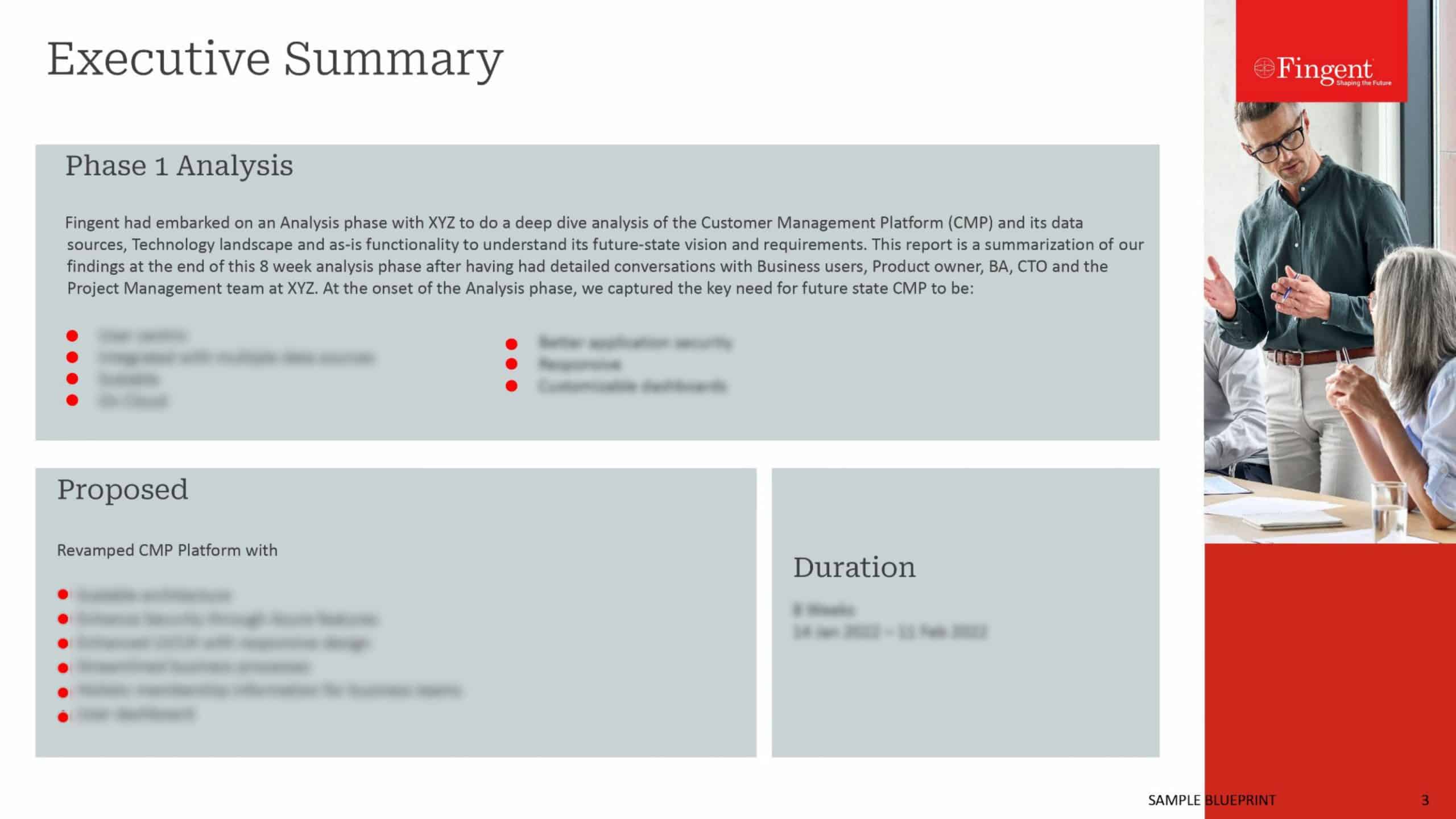

How can Fingent Help Leverage AI Capabilities with Customized Solutions?

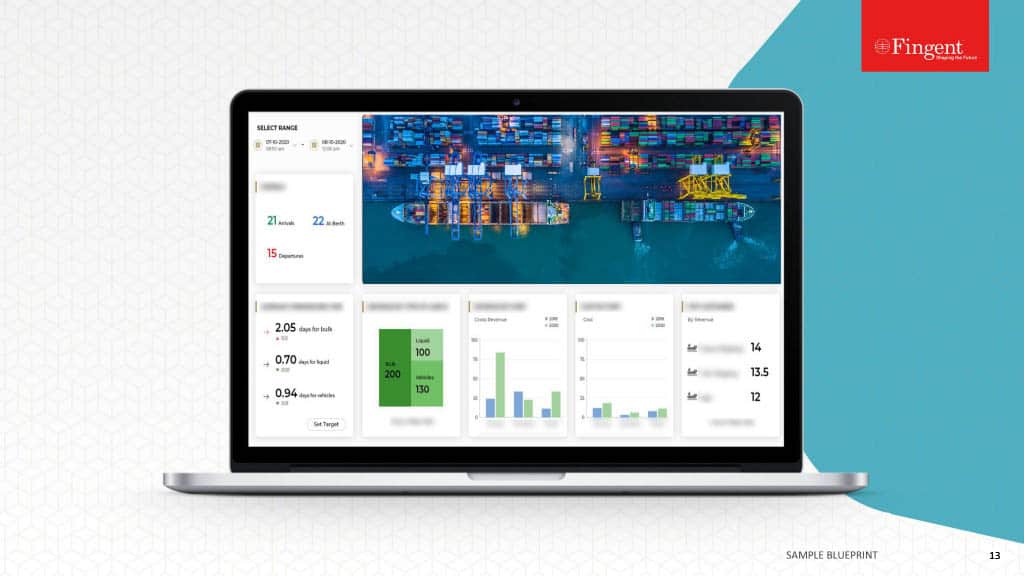

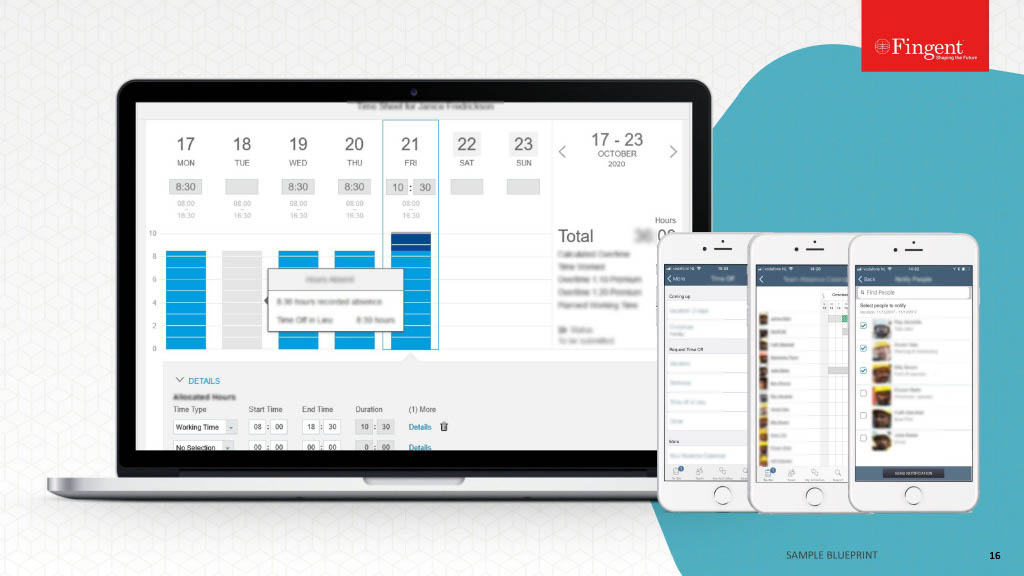

For optimal performance, you need a customized manufacturing solution. Custom software solutions can reduce costs and provide unparalleled product quality.

Fingent helps you leverage AI with customized software solutions tailored to your unique needs. By integrating AI, machine learning, and IoT, Fingent provides top-notch automation and efficiency.

Some solutions that Fingent can make possible for you:

- ERP manufacturing software

- Computer Aided Manufacturing (CAM)

- Inventory Management solutions

- Quality Management Systems

Leverage technology like Advanced Robotics, Augmented and Virtual Reality, and drive a new wave of innovation. Always stay one step ahead of the competition.

Come revolutionize your manufacturing process with our expert software development team. We guarantee tailored, cost-effective software solutions that will optimize your business processes. Give us a call today and let’s get the conversation started.

Stay up to date on what's new

Recommended Posts

12 Dec 2025 B2B

Legacy App Modernization: How AI Is Turning Modernization from an Option into a Mandate

Legacy apps modernization is a business necessity – there’s no two ways about it. AI, cloud, automation, and more – these are the key drivers transforming the digital economy. There……

26 Mar 2025 B2B

Agentic AI vs Traditional AI: Understanding The New Era of Technology

Artificial Intelligence is shifting from simple rule-based programs to sophisticated neural networks capable of near-human reasoning. Still, in a way, it’s still like a machine that takes whatever instructions it……

Featured Blogs

Stay up to date on

what's new